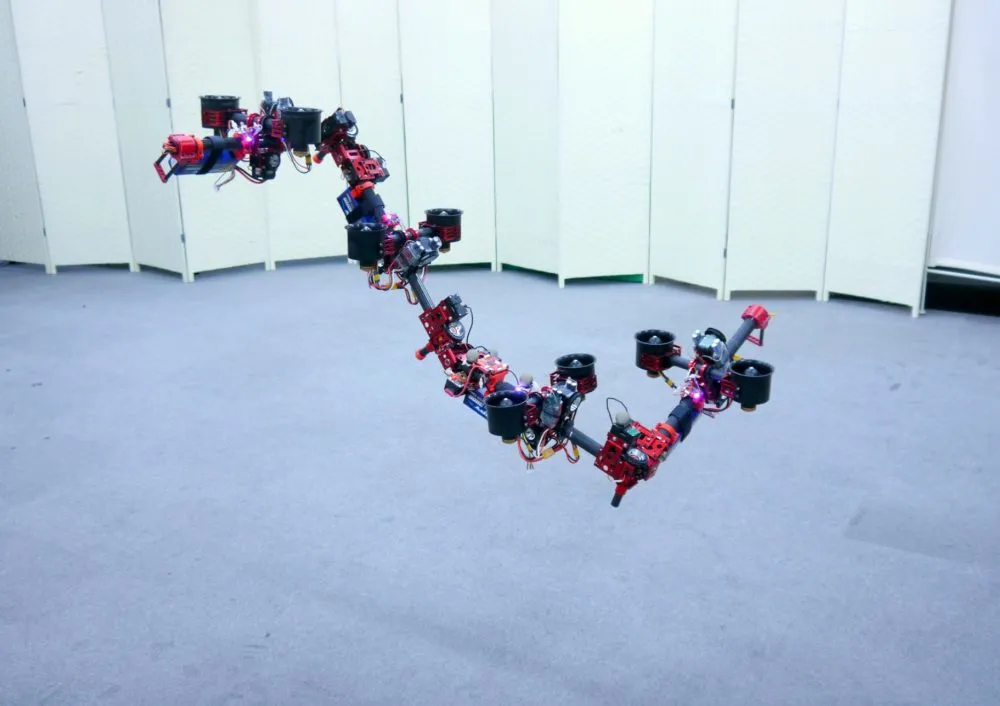

We currently have two completed base UAV designs that are waiting to be prototyped by 3D printing which will allow us to target any changes in design that need to happen, as well as performing test flights which will allow us to analyze ways to further improve the designs functionality.

These test flights will focus on the following issues: stability, control, speed, and battery life. We find the typical flight time of current UAVs very limiting. Time is money, and the longer you're able to keep your UAV in flight the more valuable it is to you.

We aim to achieve a 45 minute continuous flight time through use of multiple batteries in a parallel configuration, power management, and light weight designs.

Once all the modifications have been made, we will make machined molds for ABS injection molding production!

We are hoping to raise $10,000 for the following:

With my experience in research and development projects on large aircraft I personally know that redesigns are going to happen. There's no getting around that.

I'm expecting 2 months of work to fix all aesthetic and mechanical issues with the airframe after the prototypes are 3D printed.

I'm expecting about 4 months to get the electronics dialed in and functioning properly as well as experimenting with multiple battery configurations and microcontroller power efficiency.

After that it's test flying time and I expect another 2-3 months of resolving issues that arise during this phase. Once all the bugs are worked out its production time!

I am a very motivated and creative individual and I will continue to crank out new and interesting designs that I can't wait to share with you!